The new Pégas Scroll Band Saw removes more wood from blanks faster and easier

By the Staff of Woodcarving Illustrated

$1,440 plus S&H

Call 800-847-4188 or e-mail sales@grobetusa.com to find a local retailer

Pégas’ new Scroll Band Saw might change how you look at projects—it certainly has for us! The first band saw to accommodate a continuous scroll saw-sized blade, it combines the power of a band saw with the accuracy and tight turning radius of a scroll saw. With this amazing new tool, you can cut carving blanks with extreme accuracy, saving hours of time removing excess wood and skipping to the fun details much faster. It can’t cut inside frets for pierced relief; for that, you’ll still need a conventional scroll or coping saw. But for everything else, it’s an absolute gem.

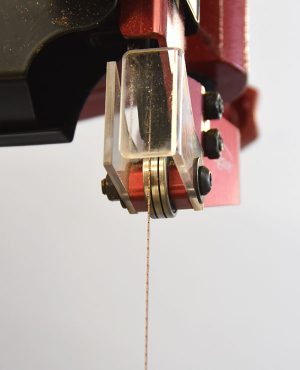

Dual precision-grooved bearings keep the blade aligned in tight turns.

How it Works

The heart of the saw is two precision-grooved bearings—one above the saw table and one below it—which support the blade as you cut. Without these bearings, the blades would snap whenever you made a tight turn. But with them positioned properly, it cuts a 1/4″ (6mm)-diameter circle in a piece of 4″ (10.2cm)-thick basswood as easily as a scroll saw does on wood one-quarter of the thickness.

Blade tension plays a big part in making square and accurate cuts. The proper tension is subjective: too little and the blade wanders and gives you curved cuts; too much, and the blade is more likely to break. Pégas suggests treating the band saw blades like you would a scroll saw blade: Move the blade guide to the uppermost position. Then press on the side of the blade. As a baseline, Pegas recommends tensioning the blade so it flexes 1/8″ (3mm) to 5/32″ (4mm). We tensioned the saw like this and it cut well on the carving blank we used as a test.

The saw is large enough to cut 6 1/4″ (15.9cm)-thick wood. The table is 16″ (40.6cm) square; the left side tilts to 15° and the right side tilts down to 45°. It’s been precision-engineered to use blades as small as a #5 scroll saw blade at 0.0142″ (.36mm) thick and 0.0402″ (1.02mm) wide.

Testing the Saw

To test the unit, we cut out a blank for Frank Napoli’s “I Prefer Brie” (see page 82) from a piece of basswood using the #12 blade that comes installed on the saw.

We were shocked at how fast the saw cut—and how easy it was to control. When cutting with the grain, we noticed some smoke coming out of the cut, which wasn’t a surprise. The small teeth of most scroll saw blades clog easily when cutting with the grain. But when we looked at the cut blank, we only saw a few areas where the wood was actually scorched, and those were where we made tight turns. We attribute that more to the new users than to the saw itself.

We did struggle a bit to make particularly tight turns where a curve turned back upon itself, as with the areas around the ears. With practice or a smaller blade, however, those curves would be easier.

Proper tensioning is important. The blade tension should be set similar to that of a scroll saw, approximately 1/8″ flexion.

We cut the entire rat without breaking a blade, which was surprising given our inexperience with this unit. It seems that as long as you keep the blades within the grooves in the bearings, you’ll be fine. This means you can’t make a 90° pivot turn by pulling back slightly on the blade; it also means that if you inadvertently pull the blade out of the bearing slot, you have to reposition it before continuing.

Also worth noting is the blade’s high-quality manufacturing. Think about it—you need to weld the two ends of the tiny blade together to create one continuous loop. A lesser product would have snapped under a beginner’s hand.

Side Notes

Our one small quibble was the clear acrylic plastic guard at the top of the blade. It collects sawdust right where we you’re trying to see, so you’ll want to keep a can of compressed air handy. We also suggest adding an aftermarket light that uses a magnet to attach to the saw. And keep in mind that only Pégas makes blades for this saw, so you won’t be able to run down to your local hardware store to pick up a new one.

Pricing

At $1,440, the saw is in the range of some of the priciest 14″ (35.6cm) band saws, such as the Shop Fox, Jet’s 414500, and the Laguna Tools. Blades range from $25 for a #5 blade to $30 for a #14 blade. You need to change the top and bottom bearings based on blade size, and extra bearings sets cost $99 each. (The saw comes with bearings that accommodate #9, #11, and #12 blades, and the #9 and #12 blades are included.)

Overall Opinion

This saw is a total rough-out wiz. If your primary use for a band saw is to cut down blanks for carving projects, take a serious look at this unit—it will save you tons of time. Good for any type of trimming, it can quickly and easily cut big blocks of wood down to size. It even cuts thick hardwood accurately and quickly, and the cut is perfectly square from front to back, allowing for more accurate joints. Yes, it’s expensive, but it’s worth every penny. Anyone starting a shop from scratch—or looking to upgrade—would do well to make this saw the centerpiece of their plans.

See the full article in Woodcarving Illustrated Summer 2019, Issue #87.